Sign up. Be inspired. Get clicking.

Boeing and Airbus' sustainable aviation fuel initiatives

11 January 2023

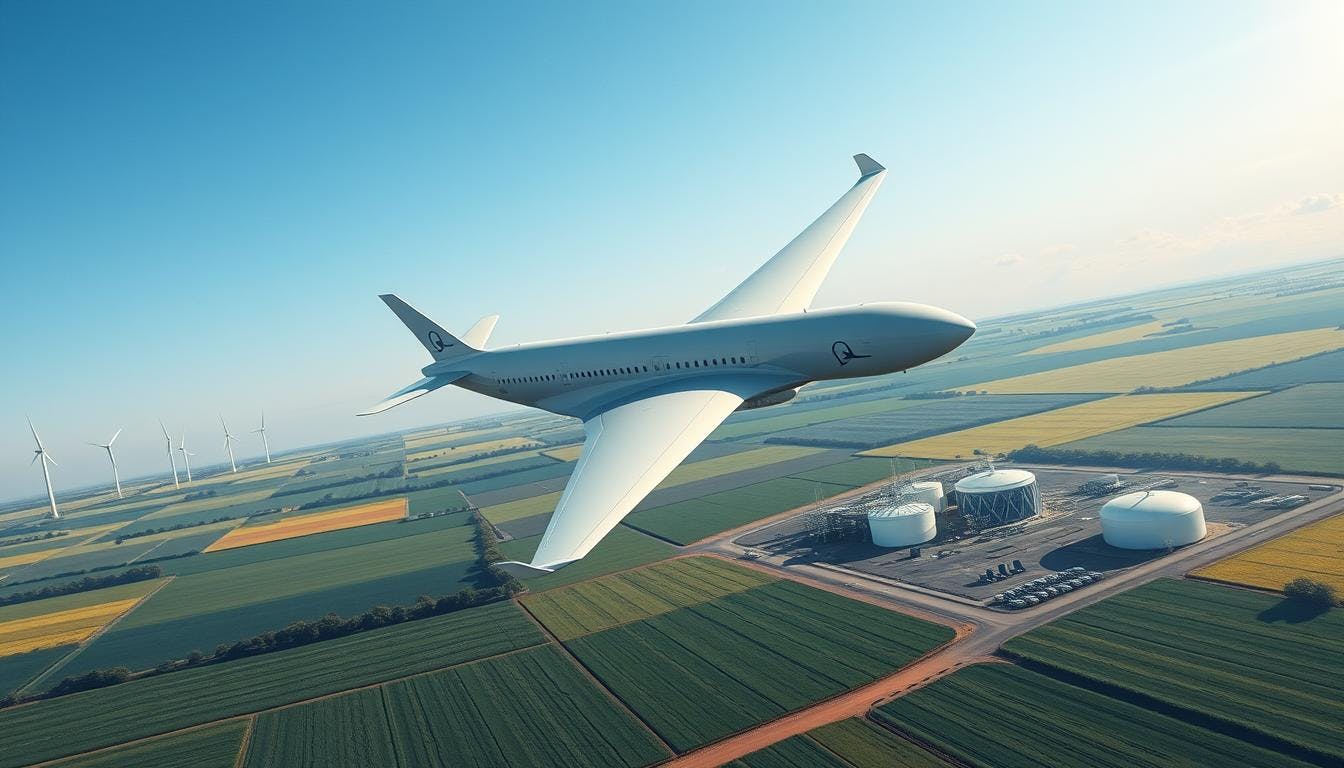

The aviation industry is indeed shifting rapidly, with Boeing and Airbus playing prominent roles in promoting Sustainable Aviation Fuel (SAF). Boeing, working with the U.S. Department of Transportation and the FAA, is committed to advancing SAF use both domestically and internationally, especially among Asia-Pacific countries.

Airbus has also been actively testing SAF, recently conducting 100% SAF flights with its A321 Neo model. Their initiatives align with industry goals of achieving net-zero emissions by 2050, as SAF reduces carbon emissions over its lifecycle by up to 85% when compared to conventional jet fuel.

Despite these efforts, SAF currently comprises only about 0.1% of total jet fuel use globally, illustrating the need for significant scaling to meet industry and governmental targets, such as the ICAO’s 5% SAF usage target by 2030.

Understanding sustainable aviation fuel (SAF) and its environmental impact

The aviation sector is increasingly focused on reducing its environmental impact, with sustainable aviation fuel (SAF) emerging as a promising alternative. SAF can reduce lifecycle CO₂ emissions by up to 80% compared to traditional jet fuel, largely due to its lower-emission production processes rather than the combustion itself.

Current SAF Usage in Global Aviation

While SAF offers substantial potential, its uptake remains limited. In 2023, global SAF production exceeded 600 million litres, marking a significant increase from previous years. However, this still represents only around 0.2% of total aviation fuel, highlighting the early stage of SAF integration within the sector. The problem is that SAF is significantly more expensive at the moment compared to the current conventional petroleum-based jet fuel. Airlines and logistic service providers showed an average well-to-pump (WTP) cost of $6 per gallon for SAF — almost three times the current price of fossil jet fuel, which at the time of writing sits at $2.29 per gallon.

However, efforts are underway to increase SAF use, with a goal of 15% adoption by the end of 2024 and at least 30% by 2030. This underscores the industry’s commitment to reducing emissions from air travel.

Carbon Footprint Reduction Potential

SAF’s value lies in its production using renewable feedstocks that recycle atmospheric carbon, which helps lower reliance on fossil fuels. Given aviation's contribution to global emissions, SAF is regarded as important for advancing towards lower-carbon operations.

Lifecycle Advantages of SAF Adoption

Beyond emissions reduction, SAF brings broader benefits for sustainable aviation. As investment in SAF expands, the sector anticipates enhanced availability and cost reductions, paving the way for more responsible and future-oriented air travel.

Boeing and Airbus sustainable aviation fuels USA: collaborative initiatives

Boeing and Airbus are partnering in the U.S. to advance the use of 100% Sustainable Aviation Fuel (SAF) for aviation. Boeing is leading this significant effort, with Airbus contributing as the deputy lead, in an initiative that explores how fully unblended SAF can power commercial aircraft. The primary aim of this project is to understand the feasibility of using 100% SAF on current and future aircraft models, with the ultimate goal of making air travel net-zero by 2050.

Both companies are actively conducting tests to gather essential data on SAF’s performance and its environmental impacts, including reductions in non-CO₂ emissions, such as soot and contrails, which are known to contribute to aviation’s climate impact. Airbus has recently conducted tests with a range of aircraft, including the A321neo and A350, powered by SAF to explore these effects in detail. This data is crucial for supporting wider industry adoption of SAF, which currently constitutes just 0.1% of all aviation fuel used globally, despite its potential to significantly cut carbon emissions over traditional fuels.

Production methods and technology behind SAF manufacturing

The aviation industry is evolving towards more sustainable practices. Significant progress is being made in the development of sustainable aviation fuel (SAF), which can substantially reduce carbon emissions compared to traditional jet fuel.

HEFA process and feedstock sources

The Hydroprocessed Esters and Fatty Acids (HEFA) process is central to SAF production, transforming waste fats and vegetable oils into jet fuel. This method, widely adopted by companies, utilises resources like used cooking oil and non-food-grade plant oils to create SAF efficiently.

Alcohol-to-Jet conversion technology

Alcohol-to-Jet (AtJ) technology also contributes to SAF's growth. This process, advanced by companies like LanzaJet, converts ethanol and other alcohols into jet fuel, achieving emission reductions of up to 70% compared to fossil fuels. AtJ SAF is compatible with existing aircraft and fuel infrastructure, facilitating broader adoption.

eFuels and Power-to-Liquid solutions

Emerging options like eFuels and Power-to-Liquid (PtL) solutions use captured CO₂ and renewable hydrogen to create fuel. With this technology, PtL SAF has the potential for very low lifecycle emissions and minimal resource requirements, positioning it as a highly sustainable solution for the future.

As the aviation sector aims to achieve net-zero emissions by 2050, these diverse SAF pathways are instrumental in reducing the industry's carbon impact and advancing towards cleaner air travel.

U.S. government support and policy framework for SAF development

The U.S. government is playing an essential role in advancing Sustainable Aviation Fuel (SAF) by partnering with the Department of Transportation, the Federal Aviation Administration (FAA), and major companies like Boeing. Their efforts focus on solving key challenges such as finding reliable feedstocks for SAF production and developing policies specifically tailored to support SAF.

A major initiative involves collaboration with the Asia-Pacific Economic Cooperation (APEC) economies, aiming to improve SAF use within the region and assist U.S. fuel suppliers in meeting global aviation decarbonisation targets. In addition to regulatory work, the U.S. government is funding research and constructing facilities to produce and transport SAF, thereby supporting both the domestic fuel industry and the broader effort to reduce aviation's carbon impact.

Boeing's strategic partnerships and investment in SAF infrastructure

Boeing has indeed been making significant strides in integrating Sustainable Aviation Fuel (SAF) into its operations. The company is collaborating with the Roundtable on Sustainable Biomaterials (RSB) to identify sustainable feedstocks for SAF, including rice husks and agricultural waste in Southeast Asia. Boeing's commitment to SAF is further demonstrated by their recent purchase of 9.4 million gallons for 2024, marking their largest SAF purchase yet. This purchase will support both their environmental demonstrator program and U.S. commercial operations.

Additionally, Boeing has been working with companies like EPIC Fuels and Avfuel to increase SAF availability and support the broader aviation industry's transition to sustainable fuels. They aim to increase SAF's use through ongoing investment, research, and policy advocacy, helping make flying more sustainable while supporting global decarbonisation efforts.

Airbus's commitment to SAF implementation in American operations

Airbus is making significant strides in the use of Sustainable Aviation Fuel (SAF). The company has set ambitious goals, aiming for at least 15% of its fuel to be SAF by 2024 and 30% by 2030. Since 2016, Airbus has allowed customers to choose SAF for new planes, contributing to a reduction in aviation-related carbon emissions. They are also conducting tests on planes using 100% SAF to assess its environmental impact.

Airbus is also leading efforts to reduce emissions from employee travel, supplying SAF for business trips in partnership with airlines like Volotea and AirCorsica. They are striving to make their operations carbon neutral by 2050 and are exploring new technologies like electric and hydrogen-powered aircraft to support this goal.

Through their involvement in ICAO's CORSIA programme, Airbus is collaborating with others in the aviation industry to ensure sustainable development and promote SAF on a global scale.

Overcoming supply chain and cost challenges in SAF production

The US commercial aviation industry is facing significant challenges with Sustainable Aviation Fuel (SAF), as only 0.1% of global jet fuel demand is currently met by SAF. This highlights the urgent need to increase SAF production to meet growing demand.

One of the major hurdles in scaling up SAF production is finding sufficient feedstock. Current sources such as used cooking oil and plant waste are limited, and their collection can be difficult. Additionally, the process of converting these materials into SAF is expensive, requiring more infrastructure and investment.

To make SAF more competitive in the market, efforts are underway to reduce its cost relative to traditional jet fuel. Government policies like the Inflation Reduction Act in the US and Europe’s ReFuelEU initiative provide financial incentives for SAF production, aiming to lower its price and make it more viable for widespread use.

For SAF to reach its potential in the US, it is essential for industry stakeholders to collaborate and secure long-term support. This will help overcome the technical and financial barriers and ensure SAF can play a central role in decarbonising aviation.

Industry collaboration and cross-sector partnerships

Boeing and Airbus are indeed making significant strides in developing and deploying Sustainable Aviation Fuel (SAF) as part of their commitment to decarbonising the aviation industry. Their collaboration aims to address the challenges faced by the aviation sector in reducing carbon emissions.

Boeing has joined various initiatives to support SAF growth, such as partnering with Masdar in the UAE and joining the CCITNZ group. These efforts focus on improving SAF production and supporting the development of related policies. Airbus, on the other hand, is working closely with airlines, airports, and other stakeholders to create a robust system that encourages the use of sustainable fuels in aviation. Both companies are leveraging their expertise and influence to help the sector transition to cleaner fuel sources, with an overarching goal of achieving net-zero emissions for aviation.

Their combined efforts are essential to ensuring the aviation industry meets its long-term sustainability targets, including the White House's SAF Grand Challenge, which aims to produce 3 billion gallons of SAF annually by 2030.

Future outlook for SAF adoption in U.S. commercial aviation

The aviation industry is making significant strides towards reducing carbon emissions by increasing the use of Sustainable Aviation Fuel (SAF). The goal is for major advancements by 2030, with expectations for cleaner flying.

2030 industry goals and milestones The International Civil Aviation Organization (ICAO) has set a target for aviation fuel to be 5% less polluting by 2030. Airlines have also committed to using more SAF, with projections to use over 20 million metric tons by 2030.

Technology innovation roadmap The ultimate aim is for all aircraft to run on 100% SAF by 2030. This will lead to the development of new technologies for SAF production and usage, helping to reduce the environmental impact of air travel.

Market growth projections Currently, SAF usage is growing slowly, but by 2030, production is expected to increase to between 11 million and 25 million metric tons. However, challenges remain, such as cost reduction and improving supply chains.

The outlook for SAF in the U.S. aviation industry looks promising. With ambitious goals, advancing technology, and cooperation across the sector, significant progress towards cleaner flying is expected soon.

Regional SAF production hubs and distribution networks

There is a strong effort in the U.S. to establish regional hubs for Sustainable Aviation Fuel (SAF). Boeing is exploring over a dozen countries to determine the most effective ways to produce SAF using locally available resources such as agricultural waste and wood chips. The goal is to create a robust SAF network by leveraging existing materials to meet the increasing demand for cleaner aviation fuel.

The Asia-Pacific Economic Cooperation (APEC) is also involved in this initiative, assisting U.S. fuel producers and airlines in overcoming challenges related to the distribution of SAF. Collaborative efforts are essential to ensure these solutions are realised.

Local SAF hubs will make it easier and more cost-effective to transport fuel to aircraft while reducing the carbon footprint associated with long-distance fuel transportation. This approach not only improves efficiency but also supports the reduction of emissions across the aviation sector.

17 South Street

Auckland 1010

New Zealand

info@carbonclick.com- -

- X

Subscribe now to stay up to date with CarbonClick, carbon offsetting and climate action.

By signing up you agree to our Privacy Policy.